Fine Porcelain Stoneware

Ceramic tiles obtained via pressing, with low porosity and made of a bright mix that can be uniformly coloured or shaded using powder mixes and grains of different sizes.

The composition of the mix is very similar to that of vitreous china but raw materials are selected in order to contain the minimum percentage of iron oxides. The mix is pressed, with specific loads higher than 50% compared to vitreous china. The firing cycle lasts less than one hour at a temperature of 1400°C.

The manufacturing process for fine porcelain stoneware creates a product that is highly resistant to frost and acids with an excellent mechanical resistance.

Glazed Porcelain Stoneware

The application of a layer of glaze on the porcelain stoneware body. These materials are particularly suitable for residential use.

Technical Porcelain Stoneware

The most sophisticated single-load and double-load pressing techniques for processing atomised and micronised powders are used to manufacture products with high technical standards.

Their high technical performance allows them to be used in advanced architectural projects.

Coloured-in Body Porcelain Stoneware

The random mixing of atomised and micronised powders creates aesthetic effects in the ceramic body, further enhanced by surface applications protected by transparent crystalline.

Their attractive appearance and technical performance make these products suitable for residential and light commercial use.

Shading

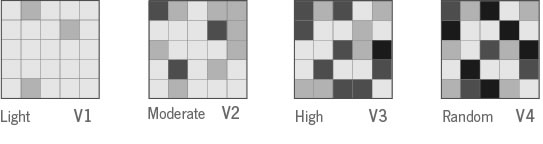

Products with the symbol below (V1-4), indicate the range has a degree of shade variation from tile to tile, characterised by a light to random finish to the surface.

Calibration

The “calibration” of the tile is the final finished size of the item post production.

Most tiles ceramic and porcelain are produced oversized and there is a degree of shrinkage during the firing process, which results in the tile becoming closer to intended size. The calibration on a non-rectified tile can vary a little from batch to batch. A rectified tile will have a calibration, final size that is set and more regular, as the rectification process takes the finished size to a final dictated size.

Please see chart for calibration sizes (for items where information is available).

Wear Grade 1

Floor coverings in areas that are walked on essentially with soft soled footwear or bare feet without scratching dirt (for example residential bathrooms and bedrooms without direct access from the outside).

Wear Grade 2

Floor coverings in areas that are walked on by soft soled or normal footwear with, at the most, occasional small amounts of scratching dirt (for example rooms in the living areas of homes but with the exception of kitchens, entrances, and other rooms which may have a lot of traffic). This does not apply to abnormal footwear, for example hobnailed boots.

Wear Grade 3

Floor coverings in areas that, with normal footwear, are walked on more often with small amounts of scratching dirt (for example residential kitchens, halls, corridors, balconies, loggias and terraces). This does not apply to abnormal footwear for example hobnailed boots.

Wear Grade 4

Floor coverings in areas that are walked on by regular traffic with some scratching dirt so that the conditions are more severe than Class 3 (for example entrances, commercial kitchens, hotels, exhibition and sale rooms).

Wear Grade 5

Floor coverings in areas that are subject to severe pedestrian traffic over sustained periods with some scratching dirt, so that the conditions are the most severe for which glazed floor tiles may be suitable (for example public areas such as shopping centres, airport con-courses, hotel foyers, public walkways and industrial applications).

This classification is valid for the given applications in normal conditions. Consideration should be given to the footwear, type of traffic and cleaning methods expected and the floors should be adequately protected against scratching dirt at the entrances to building by interposing footwear cleaning devices.

Slip Resistance

There are two main measures of slip resistance used in today’s tile industry: ‘R ratings’ which refers to a value derived from ramp testing to record slip resistance, or ‘PTV’ which stands for ‘Pendulum Test Values’, where a swinging arm with a rubber foot is allowed make contact with the tile being tested and grip assessed.

R Rating

The R Rating test comprises a ramp covered with the flooring of choice being inclined a degree at a time until someone walking on the ramp slips. During the test, the inclined surface is contaminated with either soapy water or engine oil. The R Rating given for the tile is based on the angle at which the participant starts to slip.

For all the tiles in the Minoli product portfolio, where possible we will state the slip resistance indicated by an ‘R’ rating from R9 to R13, ranging from:

- R9 (for use indoors, ideally for dry areas)

- R10 (typically for use indoors, including areas that may become moderately wet, such as kitchens)

- R11 (the highest value – recommended for outdoor use on external areas)

If you require more technical details concerning the safety characteristics, please contact us directly.

Pendulum Test Values (PTV)

Another measure of slip resistance is the Pendulum Test Value.

The Pendulum Test records results for tiles in both wet and dry conditions and the higher the Pendulum Test Value, the greater the level of slip resistance.

If you require more information about PTVs for our products, please ask and we will provide results where available from the manufacturer.

Our customers’ safety is of great importance to us so please let us know if you have any doubts or questions about slip resistance and tile suitability.

Frost Resistant

Tiles that have been classified as ‘frost resistant’ has been tested for cold conditions when using for external areas.

Outdoor Tiles

More ranges are now being produced with coordinating versions in thicknesses of 20mm and over, specifically for use outside on patios, garden paths, terraces, balconies, walkways, swimming pools and driveways for both residential and commercial settings.

Whilst some 9mm+ tiles may be suitable for outdoor use with the right installation techniques, frost and slip resistance, and wear grade should also be considered. Tiles with 20mm+ thickness offer high resistance to loads, making them suitable for heavy foot-traffic areas, outdoor driveways and car standing.

There are many flexible methods for installing outdoor porcelain tiles depending on the substrate, surface and specifics of the site. Whilst we recommend you always refer to the manufacturer’s instructions for each particular product and consult with a qualified technician, we have provided some ‘Installation Rough Guides’ to provide an overview of the suitable applications and relatively straightforward methods of fitting these exciting new alternatives to traditional exterior paving.

Extra Large format / XL Tiles and Slabs

Suitable for floors and walls, new production and transportation techniques allow for more expansive and extra-large sized tiles. Products with a Large Format / XL classification have a dimension of between 120cm and 320cm and some with reduced 6mm thicknesses to make them less heavy and easier to handle and transport.

Image Usage Disclaimer

The images contained on this site are for a representational example only. Web/screen viewing cannot reproduce a true likeness of colour, tone or texture. Reference to a sample is essential.